Pipe

Based on Manufacturing Process Pipes can be classified as below

- Seamless Pipe & Tubes

- Welded Pipe & Tubes ERW – Electrical Resistance welded.

Seamless Pipe & Tube Manufacturing Process

Seamless pipe is Strongest amongst all pipes type as it has a Homogeneous structure throughout pipe length.

- Seamless pipes & tubes are manufactured in a verity of size and schedule. However, there is a Restriction on the manufacturing of large diameter pipe & tubes .

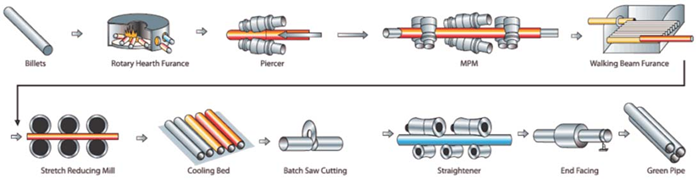

Mandrel Mill Process

In the Mandrel Mill pipe manufacturing process, the steel billet is heated to high temperature in the rotary furnace. A cylindrical hollow, which is also known as mother hollow, is produced with the help of a rotary piercer and set of roller arrangement that keeps the piercer at the center of the billet.

The outside diameter of the piercer is approximately that of the inside diameter of the finished pipe. With the help, secondary roller arrangement outside diameter and thickness are achieved.

This process is used to make smaller sizes of seamless pipe, typically 1 to 6 inches (25 to 150 mm) diameter.

- The ingot of steel is heated to 2,370 °F (1,300 °C) and pierced.

- A mandrel is inserted into the tube and the assembly is passed through a rolling (mandrel) mill.

- Unlike the plug mill, the mandrel mill reduces wall thickness continuously with a series of pairs of curved rollers set at 90° angles to each other.

- After reheating, the pipe is passed through a multi -stand stretch-reducing mill to reduce the diameter to the finished diameter.

The pipe is then cut to length before heat treatment, final straightening, inspection, and hydrostatic testing

Plug Mill Process

Mannesmann was a German engineer who has invented this pipe manufacturing process. The only difference between the Plug mill process and the Mandrel mill process is that in the mandrel method inside diameter is achieved in a single pass whereas in Mannesmann multi-stage reduction is possible.

- This process is used to make larger sizes of seamless pipe, typically 6 to 16 inches (150 to 400 mm) diameter.

- An ingot of steel weighing up to two tons is heated to 2,370 °F (1,300 °C) and pierced.

- The hole in the hollow shell is enlarged on a rotary elongated, resulting in a short thick-walled tube known as a bloom.

- An internal plug approximately the same diameter as the finished diameter of the pipe is then forced through the bloom.

- The bloom containing the plug is then passed between the rolls of the plug mill.

- Rotation of the rolls reduces the wall thickness

- The tube is rotated through 90° for each pass through the plug mill to ensure roundness.

- The tube is then passed through a reeling mill and reducing mill to even out the wall thickness and produce the finished dimensions.

- The tube is then cut to length before heat treatment, final straightening, inspection, and hydrostatic testing.

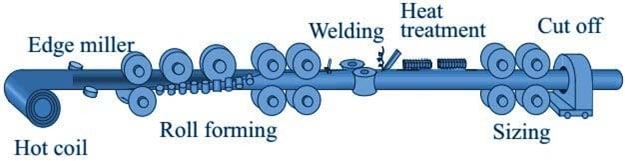

Welded Pipe & Tube Manufacturing Process

Electric Resistance Welded (ERW)

- Solid phase butt weld, was produced using resistance heating & high pressure to make the longitudinal weld (ERW),

- Nowadays Most pipe mills now use high frequency induction heating (HFI) for better control and consistency. However, the product is still often referred to as ERW pipe, even though the weld may have been produced by the HFI process.

- The defects that can occur in ERW/HFI pipe are those associated with strip production, such as laminations and defects at the narrow weld line.

- Lack of fusion due to insufficient heat and pressure is the principal defect, although hook cracks can also form due to realignment of nonmetallic inclusions at the weld interface. Because the weld line is not visible after trimming, and the nature of the solid phase welding process, considerable lengths of weld with poor fusion can be produced if the welding parameters fall outside the set limits.

- In addition, early ERW pipe was subject to pressure reversals, a problem that results in failure in service at a lower stress than that seen in the pre-service pressure test. This problem is caused by crack growth during the pressure test hold period, which in the case of early ERW pipe was due to a combination of low weld line toughness and lack of fusion defects.